|

| Glass |

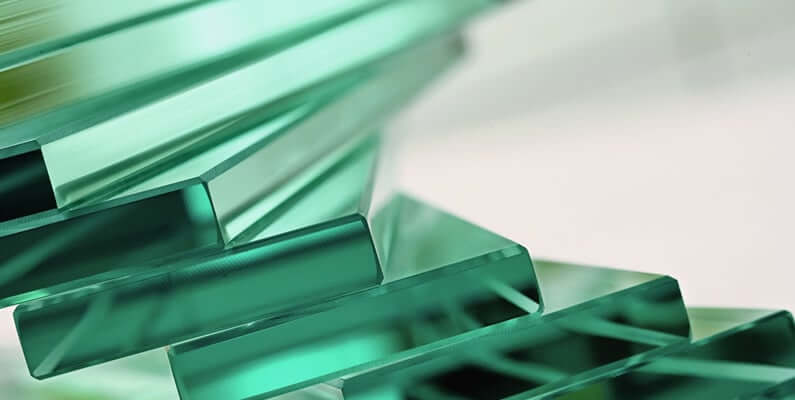

Aesthetic qualities and the absence of toxicity contribute to the active distribution of the material.

However, the only drawback of simple glass products is their fragility, especially with regard to mechanical impact.

But, despite this, the number of glass products is constantly growing, just like the amount of cullet with which it is necessary to fight, since in nature itself it practically does not disintegrate.

It is for these reasons that glass recycling is one of the most important pressing issues, which not only improves the state of the environment, but also makes it possible to lower the cost of manufactured products.

|

| Glass |

In modern conditions, utilization and processing of glass breakage is a young and actively developing industry, the advantages of which are obvious:

• low cost of recycled materials;

• minimum investment in contrast to the creation of a full-fledged enterprise for the casting of glass products;

• high payback rate, as large-scale industrial companies become customers;

• minimal labor and energy costs, since the process of recycling broken glass is fully automated.

Due to the main advantages in the post-Soviet space, there are more and more companies that specialize in glass recycling.

Mainly broken glass, as well as defective products are disposed of by re-melting of glass fractions.

In order for a broken vessel or a piece of sheet glass to become part of a new product, it needs to go through the following phases:

| Glass |

2. Primary wash. After transporting glass debris to the enterprise, it is sent to special containers, where it is cleaned of large impurities and washed.

3. Sort by color and size fractions. The most time consuming phase, since its implementation is possible only manually.

4. Crushing and grinding. After sorting the glass particles fall into a special crushing equipment, where they are subjected to grinding.

5. After crushing, all homogeneous glass mass is sent to smelting furnaces for further melting and manufacturing of new products.

Glass recycling with its recycling is one of the important processes that saves the consumption of natural resources spent on the manufacture of primary raw materials, improves environmental conditions, and reduces the existing volumes of landfills.