|

| Glass tempering technology |

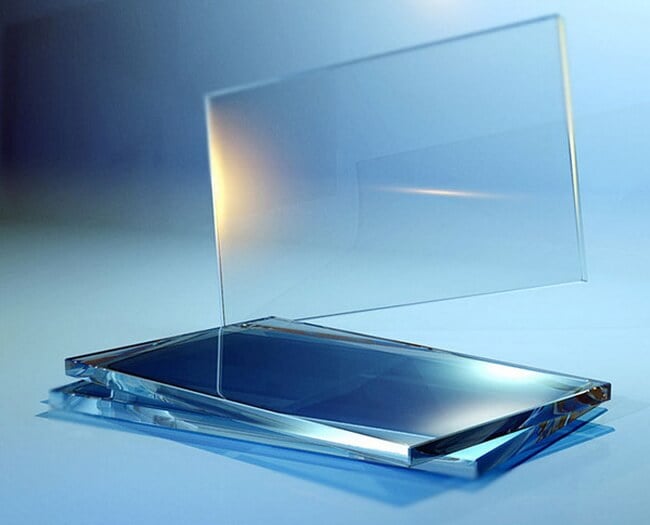

To make ordinary glass more resistant to shock loads, temperature changes, and also safer in the event of destruction, special high-temperature treatment is applied to it, followed by cooling - quenching. As a result of quenching, constant stresses remain in the glass material, due to which glass loses its uniformity and acquires new properties.

The specific properties of tempered glass

Hardened glass can not be drilled or cut - it will lead to its destruction due to the presence of internal stresses. Due to the use of glass hardening technology, it becomes 5-10 times stronger to shock loads and much more resistant to destruction due to temperature differences than ordinary glass.

If tempered glass is broken, it does not carry a danger of injury to a person, since its fragments are small, with blunt edges, which cannot be cut. If you break the usual glass, formed large fragments with sharp edges, very traumatic.

Use of glass after quenching

Quenched glass is applied:

• in construction;

• in interior design;

• in the manufacture of furniture;

• for the production of partitions, fences, showcases, • decorative structures, shower cabins;

• for production of autoglasses;

• in the production of optical, photo and video equipment and technology, as well as for the production of research equipment, instruments and tools.

Features of glass tempering technology

To create tempered glass, special furnaces are used in which glass blanks undergo special treatment. Glass hardening technology involves two stages. On the first, the glass blank is heated to a temperature above the melting point (650-800С). On the second, it cools quickly and evenly. The cooling stage is the most important and crucial in the production of tempered glass.

To the cooling rate was as high as possible, use special cooling media. Cold air is often used for cooling. It is possible to increase the cooling efficiency if liquid is used instead of air, which allows achieving a higher rate of heat release. For this purpose, various mineral oily liquids, polyethylsiloxanes, molten salts, silicone and other liquids are used on the glass hardening lines. Through the use of such liquids, it becomes possible to increase not only the tempering rate of glass, but also its intensity.

One of the types of liquids used in glass tempering technology is molten metals. They are characterized by a higher heat transfer than most organic and mineral liquids, and allow for the tempering of glass having an elevated melting point. However, the use of molten metals has its own minus - due to the high density of melts, the process of immersing glass blanks in them may be complicated.

In addition to the thermal technology of glass tempering, there is a chemical one - it is very little in demand and practically not used. This technology consists in the substitution in the crystal lattice of sodium ions, having a small size, with potassium ions, larger. As a result, tension is created in the lattice structure of the substance, which gives it the properties of tempered glass.

The specific properties of tempered glass

Hardened glass can not be drilled or cut - it will lead to its destruction due to the presence of internal stresses. Due to the use of glass hardening technology, it becomes 5-10 times stronger to shock loads and much more resistant to destruction due to temperature differences than ordinary glass.

If tempered glass is broken, it does not carry a danger of injury to a person, since its fragments are small, with blunt edges, which cannot be cut. If you break the usual glass, formed large fragments with sharp edges, very traumatic.

| Glass tempering technology |

Quenched glass is applied:

• in construction;

• in interior design;

• in the manufacture of furniture;

• for the production of partitions, fences, showcases, • decorative structures, shower cabins;

• for production of autoglasses;

• in the production of optical, photo and video equipment and technology, as well as for the production of research equipment, instruments and tools.

Features of glass tempering technology

To create tempered glass, special furnaces are used in which glass blanks undergo special treatment. Glass hardening technology involves two stages. On the first, the glass blank is heated to a temperature above the melting point (650-800С). On the second, it cools quickly and evenly. The cooling stage is the most important and crucial in the production of tempered glass.

|

| Glass tempering technology |

One of the types of liquids used in glass tempering technology is molten metals. They are characterized by a higher heat transfer than most organic and mineral liquids, and allow for the tempering of glass having an elevated melting point. However, the use of molten metals has its own minus - due to the high density of melts, the process of immersing glass blanks in them may be complicated.

In addition to the thermal technology of glass tempering, there is a chemical one - it is very little in demand and practically not used. This technology consists in the substitution in the crystal lattice of sodium ions, having a small size, with potassium ions, larger. As a result, tension is created in the lattice structure of the substance, which gives it the properties of tempered glass.